Return

Email

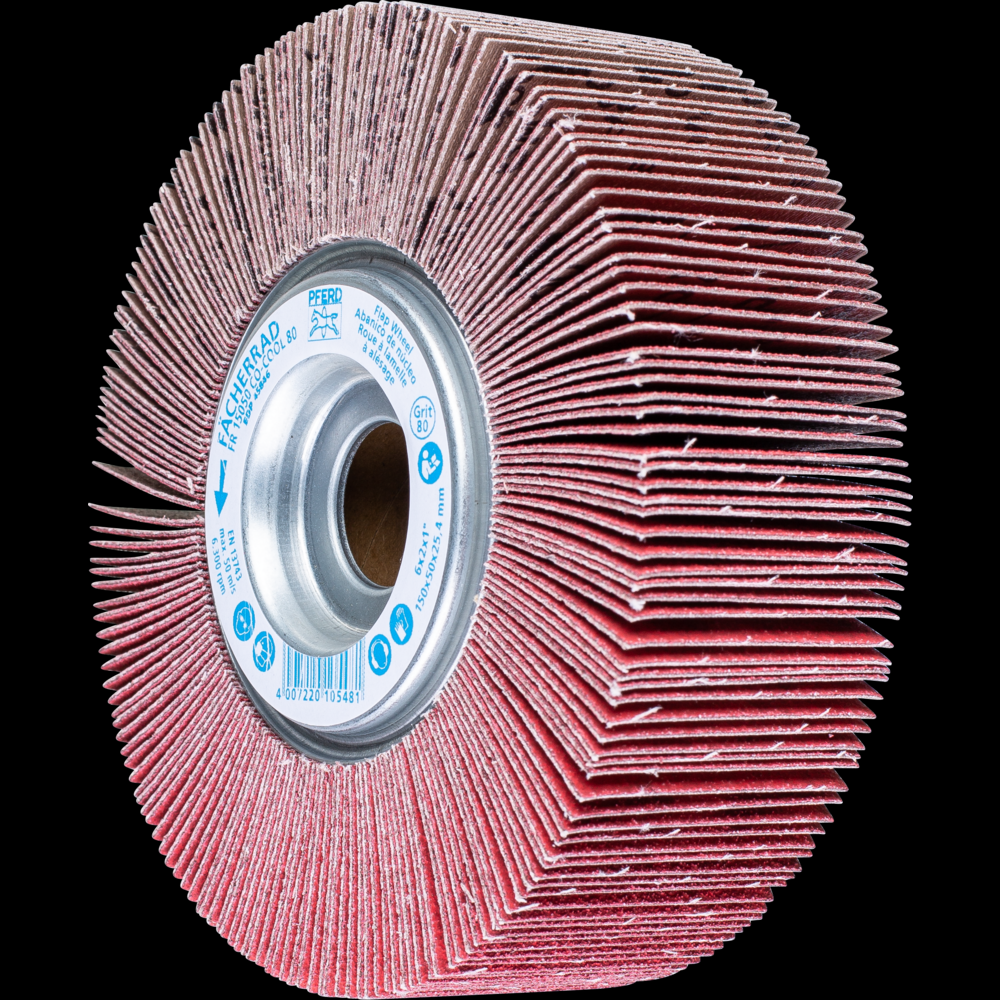

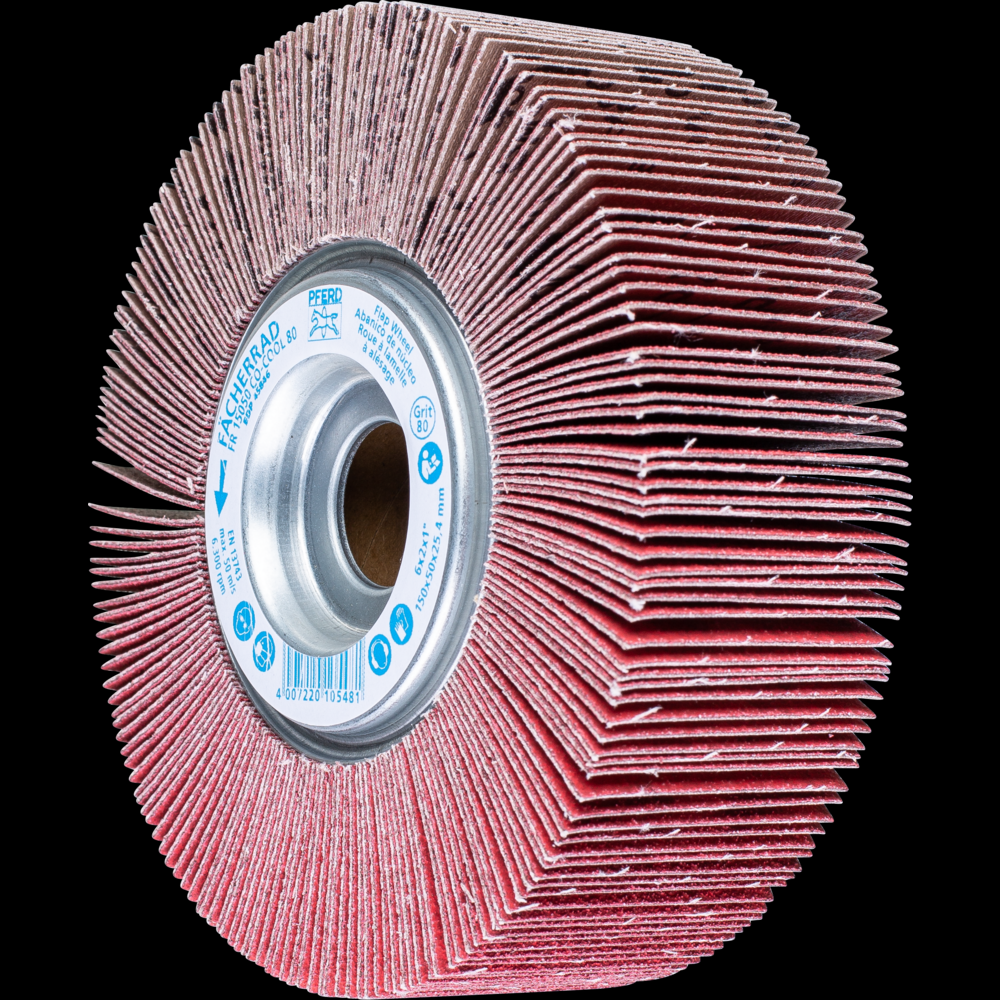

PFERD Unmounted Flap Wheel, 6" x 2, 1" Arbor, 80 Grit, Ceramic oxide CO-COOLItem is usually in stock, but we'll be in touch if there's a problem

by Pferd Inc.

PFERD Unmounted Flap Wheel, 6" x 2, 1" Arbor, 80 Grit, Ceramic oxide CO-COOLItem is usually in stock, but we'll be in touch if there's a problem

by Pferd Inc.

Call for Price

Item is usually in stock, but we'll be in touch if there's a problem

Quantity:

Add To Cart

Add To Estimate

Add To Wishlist

Compare Item

PFERD Unmounted Flap Wheel, 6" x 2, 1" Arbor, 80 Grit, Ceramic oxide CO-COOLItem is usually in stock, but we'll be in touch if there's a problem

by Pferd Inc.

Price:

Call for Price

Part Number: 60K4ZVP

UPC: 04007220105481

Vendor Item Number: 44727208

Call for Price

Item is usually in stock, but we'll be in touch if there's a problem

Quantity:

Add To Cart

Add To Estimate

Add To Wishlist

Compare Item

Technical Details

Industrial Category:

Abrasives

Industrial Subcategory:

Abrasive Wheels, Discs and Brushes

Industrial Subtype:

Flap Wheels

Category Level 4:

Unmounted Flap Wheels

Abrasive:

CO-COOL

Applications:

Deburring

Country of Origin:

DE

Diameter Hole:

1 Inch

Drive Types:

Flexible shaft drive

EAN:

4007220105481

EDP:

45846

Grit Size:

80

Item Quantity:

2

Materials that can be worked:

Aluminum

Order Quanityt:

70

Pferdergonomics:

PFERDERGONOMICS recommends flap wheels to reduce vibration and noise produced during use and to improve comfort when working.

Recommendations for use:

Flap wheel wear and the thermal load on the workpiece are reduced by decreasing the contact pressure and peripheral speed, and by adding grinding oil.

Safety notes:

Unmounted flap wheels should only be used with the appropriate clamping flanges.

UNSPNC:

31191519

UPC Code:

97758458467

Manufactured By:

Pferd Inc.

+

Additional Information

- Can be used face-down very close to edges and in corners thanks to special clamping system.

- Conforms to contours due to high flexibility.

- Consistently high stock removal rate throughout the entire service life as new, aggressive abrasive is constantly exposed.

Product Overview

With unmounted flap wheels, coated abrasive flaps are arranged radially around the core in a fan-like structure. The flexible flaps perfectly adapt to surface contours. The abrasive grain is embedded in the sturdy, flexible cloth backing material with a resinoid bond. In ISO 5429, unmounted flap wheels are designated as "flap wheels." For aggressive grinding with maximum stock removal rate on hard materials that do not conduct heat well. Consistently high performance due to self-sharpening ceramic oxide grain. Active grinding additives in the coating substantially improve the stock removal rate, prevent loading, and result in cooler grinding.

Info & Guides